In the actual production of the dry granulator, fluctuations in pressure tracking are often encountered. Generally, the pressure tracking exceeds the set extrusion pressure. This is because the force of the screw pushing down is greater than the force of the extrusion cylinder to push the pressure roller, the two pressure rollers are pushed apart by the feeding, and the gap between the pressure rollers becomes larger, so The pressure tracking exceeds the set extrusion pressure. This situation is normal, and the principle of the dry granulator is hard extrusion.

However, we found that when the equipment is repeatedly back-pressed for long-term production, the more it is done in the later stage, the blacker the extruded particles and the higher the hardness. At this time, it is necessary to manually adjust the parameters. This is because the return material itself has small particles, and its bulk density and fluidity are different from those of the new material, so it needs to manually adjust the parameters frequently. In order to solve this problem, we added PID compensation to control the speed of the roller according to the pressure in the PLC program of the equipment. The main purpose is to solve the problem that the parameters need to be adjusted frequently due to the unstable characteristics of the input materials during long-term production and processing, so that the dry granulator can automatically adjust the parameters.

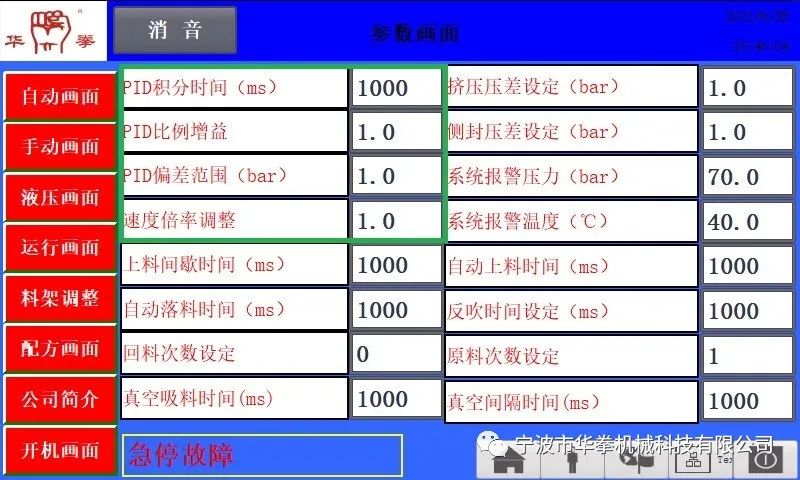

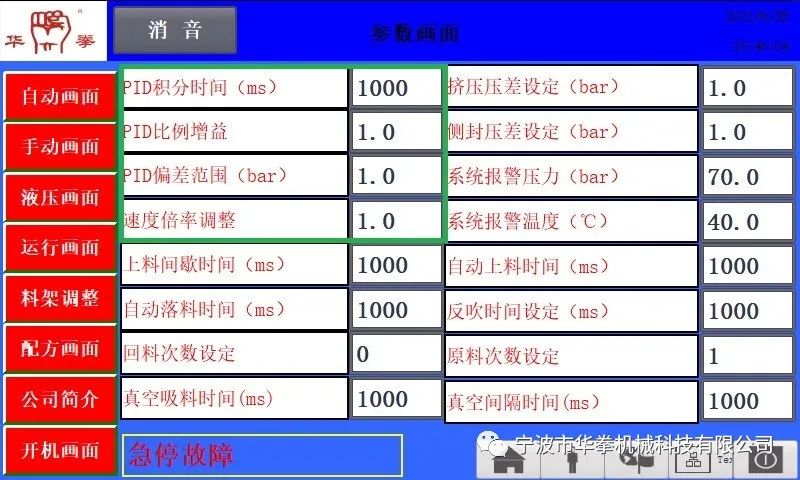

The following figure shows the relevant parameters of the PID compensation in the 19th edition program - the green box

The principle of the program is to control the speed of the pressure roller according to the deviation between the pressure tracking and the set extrusion pressure. The faster the pressure roller rotates, the shorter the pressure process of the material, and then the purpose of automatic adjustment is achieved.But sometimes the material has high sugar content and high humidity is easy to stick. We just need to set low pressure and follow high pressure to do it, such as heat-sensitive materials, materials with high sugar content, etc. If the PID compensation parameters are not changed, there will be At the beginning, the adjustment was very good, but the more the pressure roller goes, the softer the film is, and the pressure tracking becomes lower. This is the situation where the PID compensation parameters are compensating. At this time, we need to modify this program or directly shield it. Generally, change < span style="margin: 0px; padding: 0px; outline: 0px; max-width: 100%; text-decoration-line: underline; color: rgb(0, 0, 0); background-color: rgb(255, 251, 0); visibility: visible; box-sizing: border-box !important; overflow-wrap: break-word !important;">proportional gain is fine, you can change this value to a smaller value or set it to 0 directly Compensation can be shielded.

In the 21-year program, we do not need to modify the details of the PID algorithm in the parameter screen, just input the pressure difference and the corresponding growth rate that need to be increased. The program will compensate and calculate in the background, reducing the difficulty of operation. At the same time, it provides 3-stage speed-up, which is more maneuverable. Also added to display the actual value of the compensation speed, more intuitive.The following figure is the relevant parameter screen of PID compensation in the 21-year program.png)

In the 21-year version of the program, if you want to shield compensation, you can set the uncompensated fluctuation pressure difference to 200 or a large value.21 program pressureThe introduction and operation video of roller speed compensation has been newly launched on Youku. If necessary, please contact Huaquan after-sales for authorization to watch.

下午3.16.04.jpeg)

In the second half of 2021, the whole series of Huaquan dry granulators will be equipped with the roller spacing detection function, which can not only accurately detect the distance between the two pressing rollers, but also adjust the spacing between the pressing rollers. Among them, the function of adjusting the spacing of the pressing rollers, because the detected pressing roller distance is an absolute value, is another method to solve the long-term production of returning materials under suitable conditions. It abandons the traditional monitoring pressure tracking, takes the roller spacing as the monitoring unit, and achieves the purpose of stable production by adjusting the roller spacing..jpeg)

For more informationmoreFor equipment information, please consultPre-sales.

Contact of pre-sales service department ↓

————————————

Money: 13805891619

(General Manager of Sales)

Mr. Ding: 13857862172

< span style="margin: 0px; padding: 0px; outline: 0px; max-width: 100%; color: rgb(53, 53, 53); font-size: 14px; box-sizing: border-box !important; overflow-wrap: break-word !important;">(Technical Sales Manager)

—— ———————————

.png)

下午3.16.04.jpeg)

.jpeg)